-

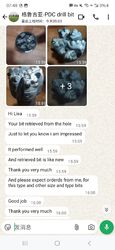

¿ Qué pasa?La calidad del trozo de tricona es buena.

¿ Qué pasa?La calidad del trozo de tricona es buena. -

Guramtu broca recuperada del agujero, solo te digo que estoy impresionado, funcionó bien. Y la broca recuperada está como nueva.

Guramtu broca recuperada del agujero, solo te digo que estoy impresionado, funcionó bien. Y la broca recuperada está como nueva.

4.5 Inch Matrix 5 Wings Diamond PDC Drill Bit For Oilfield Drilling

Póngase en contacto conmigo para muestras y cupones gratis.

WhatsApp:0086 18588475571

El Wechat: 0086 18588475571

¿ Qué pasa?: sales10@aixton.com

Si tiene alguna preocupación, ofrecemos ayuda en línea las 24 horas.

x| Color | personalizado | HS | 8207191000 |

|---|---|---|---|

| Proceso de fabricación | Mecanismo de CNC | Tipo | Herramientas de perforación de rocas |

| Resaltar | 4.5 inch PDC drill bit,matrix body oilfield drill bit,5 wings diamond drill bit |

||

Oilfield Diamond PDC Drill Bit

PDC Drill Bits Classification by Applications:

Oil & Gas drilling

- It is the most widely used bit in the Oil &Gas drilling. Hydraulic factors are very important during drilling.

- PDC bits have been used in the areas that can't be available previously, such as harder, more abrasive, and more variable formations.

- The diamond PDC bit is mainly composed of the bit body, cutting teeth, nozzle, gauge protection, and API Thread connection.

| Body material: | matrix body |

| Size: | 4.5 inch |

| Painting color: | customized |

| Condition: | new manufacture |

| Applicable industrial: | energy & mining |

| Machinery test: | as requirements |

| Place of origin: | Suzhou,China |

| Certificate: | API & ISO |

| Manufacture Processing: | casting |

| Usage: | oil/gas well |

| Warranty: | 1 year |

Cutter

The primary contact point of a drill bit is its PDC cutters, which are made of Polycrystalline Diamond Composite (PDC).

PDC bits excel at efficiently removing rock by chopping through it.

Operating in a challenging environment, PDC cutters experience frequent heating and cooling within the well.

To maximize performance, PDC cutters with superior thermal stability and minimal thermal deterioration are preferred.

These optimized cutters demonstrate higher Rate of Penetration (ROP) and enhanced wear resistance.

Nozzle

Drill bit nozzles play a crucial role in maintaining the temperature of the PDC cutters and clearing the cutting zone.

By keeping the PDC cutters cool, the nozzles contribute to their longevity and performance.

The positioning and angle of these nozzles significantly influence the effectiveness of the drill bit. Properly placed nozzles ensure efficient cooling and help prevent heat-related issues.

Additionally, the strategic arrangement of fluid channels, in conjunction with the nozzle location, facilitates improved removal of cuttings during drilling operations.

![]()

Production Processes:

![]()

Certifications:

![]()

FAQ:

| Q: You are a trading company or manufacturer ? |

| A: Manufacturer, We are a 100% real factory with over 10 years' experience in water/oil/gas wells Drill Bits. |

| Q: How about your products ? |

| A : Both of tricone bits and PDC bits strictly conform to API 7 requirements and ISO9001. we will do kinds inspections before delivery, also cover for after-sales service. |

| Q: Package Methods ? |

| A: Normally wooden case, also can be steel box; can be customized if need. |

| Q: Payment Terms ? |

| A: we accept T/T, L/C, Paypal, Western Union, etc. |

| Q: Can I visit your factory ? |

| A: Yes, we welcome you to our factory all the time, will send invitation letters if need; also can show our workshop and warehouse online. |