-

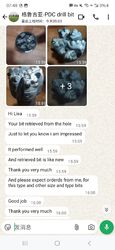

¿ Qué pasa?La calidad del trozo de tricona es buena.

¿ Qué pasa?La calidad del trozo de tricona es buena. -

Guramtu broca recuperada del agujero, solo te digo que estoy impresionado, funcionó bien. Y la broca recuperada está como nueva.

Guramtu broca recuperada del agujero, solo te digo que estoy impresionado, funcionó bien. Y la broca recuperada está como nueva.

9-1/2" PDC Drill Bit of Oil well Hard Rock Drill Bit

| Lugar de origen | Porcelana |

|---|---|

| Nombre de la marca | ENG |

| Certificación | API, ISO |

| Número de modelo | 10625 |

| Cantidad de orden mínima | 1 |

| Precio | 2000-3000 |

| Detalles de empaquetado | Caja de madera y caja de metal |

| Tiempo de entrega | 4 semanas |

| Condiciones de pago | T/T, L/C, Unión Occidental |

| Capacidad de la fuente | 5000pcs / año |

Póngase en contacto conmigo para muestras y cupones gratis.

WhatsApp:0086 18588475571

El Wechat: 0086 18588475571

¿ Qué pasa?: sales10@aixton.com

Si tiene alguna preocupación, ofrecemos ayuda en línea las 24 horas.

x| Usar | perforación de pozos de petróleo | Tamaño | 9-1/2" (241,3 mm) |

|---|---|---|---|

| Tipo | Herramienta de perforación de diamantes | Material | Diamante, acero de aleación, |

| Tipo de máquina | Industria de perforación | Tipo de procesamiento | Forjing, Casting |

| Aplicación | Taladro de roca de petróleo, minería, gas | Color | Requisito del cliente |

| Cortadores | Compacto de diamante policristalino (PDC) | Tipo | Brote de perforación de diamantes |

| Tratamiento superficial | Inserción PDC | ||

| Resaltar | 9-1/2 inch PDC drill bit,oil well hard rock drill bit,steel body PDC drill bit |

||

9-1/2" PDC Drill Bit of Oil well Hard Rock Drill Bit

1 . Desciption of PDC Drill Bit

The PDC bit is a diamond cutting tool fixed on the bit's blades, primarily used for rock drilling in oil, mining, water wells, or natural gas wells.

The bit's standards are based on the American Petroleum Institute (API) specifications. The PDC cutting teeth are made of synthetic

diamond material, which is currently the hardest known substance, providing exceptional wear resistance. Compared to roller cone bits,

PDC bits generally offer higher drilling efficiency but at a relatively higher cost.

PDC bits utilize multiple diamond cutters arranged in specific patterns to shear the rock formation. These bits are mainly categorized

into two types: matrix body PDC bits and steel body PDC bits, designed for different drilling conditions. Matrix body PDC bits are

typically used in more abrasive formations, while steel body PDC bits are often employed in softer formations.

According to the International Association of Drilling Contractors (IADC), there are much reason effected the bit drilling function effiency .

We have give the main reason as below :

- Body material

- Cutter density

- Cutter size or type

- Bit profile

All of the drill bit are manufacture according to API standard used in the drilling Industry.

The PDC drill bits size 3~22inch with 3~9Blades are available. And different classification cutter are optional according to your budget .

2. Specification:

| SPECIFICATION | |

| Size : | 9-1/2" ( 241.3mm) |

| Drill Body Type : | Steel Body |

| Blades Quantity : | 6 |

| Nozzles Quantity : | 6 |

| API Connection (in) : | 6-5/8" REG |

| Gauge Length (In): | 2.5 |

| OPERATIONAL PARAMETERS | |

| Weight on Bit (KN): | 87-178 KN |

| RPM Range(Rotary): | 100 - DHM |

| Flow Rate(lps): | 48 - 57 LPM |

| Make-Up Torque(KN): | 38--43 KN.M |

![]()

![]()

3 . PDC Bit profile

![]()

4 . Drill Bit PDC Cutters

Polycrystalline Diamond Composite (PDC) cutters are the main point of contact for a drill bit. PDC bits remove the rock mainly by shearing.

The PDC cutters are exposed to a lot of heating and cooling down the well, a very challenging environment.

PDC cutters that have lower thermal degradation and more thermal stability generally achieve higher ROP and increased wear resistance. So, optimizing the cutter is important.

![]()

5. Drill Bit Nozzles

Drill bit nozzles help clear the cutting area and cool the Polycrystalline Diamond Composite (PDC) cutters.

Effective placement of these nozzles along with the angle they are set at plays a critical role on how efficient the drill bit performs.

Fluid channels also complement nozzle placement to improve the clearing of cuttings.

![]()

6. Steel Body PDC Bits

Steel body is the opposite of matrix body. It can of withstanding high impact loads, but is softer and lacks protective features. The strength and ductility of steel give steel-bit bodies high impact resistance.

Steel bodies are considerably stronger than matrix bodies.

A beneficial feature of steel bits is that they can easily be rebuilt a number of times because worn or damaged cutters can be replaced rather easily. This is a particular advantage for operators in low-cost drilling environments.

![]()

Polycrystalline diamond compact (PDC) drill bits are different than roller cones in that they are one piece bodies with no moving parts. The fixed-cutters shred the rock, so the bit is able to operate with higher rotation speeds more efficiently in consolidated formations.

![]()